Why Is My Craftsman Chainsaw Chain Won’t Turn? Easy Fixes

You need to cut wood. And the engine on your Craftsman chainsaw starts up, but the chain not turning.

If the chain on your chainsaw isn’t turning, it could be because the chain brake is engaged, the guide bar is worn out, the chain is damaged, the chain oiler isn’t working properly, or the clutch is worn out.

A jammed chain can frustrate anyone. Even a beginner chainsaw user can easily fix this issue. I’ll explain how to fix each scenario below.

Reason for Craftsman Chainsaw Chain Not Turning

Chainsaws are useful when working properly. However, chainsaws require periodic maintenance. Check the following items if your chainsaw’s chain isn’t rotating.

Chain Brake Engaged

Sometimes the chain brake of a craftsman chainsaw is engaged and the chain stops rotating. Unawareness of a chain brake and how to disengage it can lead a saw operator to incorrectly believe the saw is broken when it only needs to be removed.

The Fix

The chain brake will be just in front of the chainsaw handle. The chain brake is activated by pushing the handle forward. To disengage the chain brake, pull the handle back.

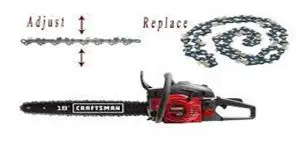

Tight Chain Tension

If your machine doesn’t have the right chain tension, it won’t last as long and the chain may stop or not turn. If you can’t easily pull the chain off, the tension is probably too high.

The Fix

You have to adjust it. Just loosen the nuts that hold the bars in place and turn the tensioning screw counterclockwise until the tension is right. Then put the nuts back on tight. If this process doesn’t work, it should be replaced.

Worn Guide Bar

Bent guide bars prevent chains from spinning. The chain won’t turn if the guide bar sprocket can’t. The bar may split if the sprocket rotates but the chain doesn’t.

A pinch in the guide bar slot rail stops a chain. The chain won’t fit through the slot rail if it’s pinched between the wood.

The Fix

If the guide bar is bent, it will be visible and need to be replaced.

The chain cannot turn if the sprocket cannot. Remove the saw’s bar and chain to verify. Remove the chain from the guide bar after removing the saw bar and chain. The bar’s tip sprocket should now be visible. Replace the guide bar if the sprocket won’t turn.

Damaged Chain

Properly operated chainsaws cut using the chain. The chain can break, rendering the chainsaw unusable. Without removing the chain from the guide bar, this damage is invisible.

After removing the chain, check the sharp bottom. Chain drag is this section. Guide bar slot rail slides chain drag. The chain becomes trapped in this section of the chain and is destroyed.

The Fix

Damage of this kind to a chain is typically brought on by operating the chain without the appropriate amount of tension or by using a sprocket that has worn out. In the event that the chain is broken, a new one will have to be purchased.

Worn Out Clutch

The clutch is the component of a chainsaw that is responsible for transferring power from the chainsaw’s motor to the sprocket, which is ultimately responsible for turning the chain so that it may cut wood.

After some period of time, the clutch shoes may become worn to the point where they are unable to transfer the power of the saw without slipping, which causes the chain to either to lose speed or come to a complete halt.

The Fix

If the clutch on your saw is worn out, the replacement work should generally be done by a dealer who services saws. This is not a particularly extensive repair, and the dealer ought should be able to finish it in thirty minutes or less (at most) using their own labor.

Damaged Clutch Band Kit

The chain is able to rotate thanks to the engagement of the clutch pads with the clutch drum.

Even if the motor will continue to operate even if the clutch pads are worn out, the clutch pads will not engage the clutch drum. As a direct consequence of this, the chain will not turn.

The Fix

Check to see that the stop lever is not in its engaged position. When the stop lever is pulled, the chain will not turn in any direction. In the event that the clutch pads have become worn, the clutch assembly should be changed.

Drum Brake Not Engaging

The clutch band drum brake engages the clutch drum to prevent it from rotating, thereby allowing the chain to turn.

In the event that the clutch band has become worn out, the motor will continue to operate, but the clutch band will not engage the clutch drum. Because of this, the chain will not turn.

The Fix

Check to see that the emergency stop lever is not engaged. If the stop lever is pulled, the chain will be unable to rotate. It is necessary to replace the clutch assembly if the clutch pads have become worn.

Non-Functioning Oiler

The purpose of an oiler on a chainsaw is to supply lubricant to the connection point between the guide bar and the chain that drives the saw. In the event that the oiler is not operating as it should, both the guide bar and the chain will become too hot to handle.

Excessive heat can cause irreparable damage to both the guide bar and the chain, leading to the failure of either component and rendering the chain unable to turn.

Failure of the oiler can be brought on by the oil pump seizing up due to ordinary wear and tear or by the oiler becoming clogged with debris.

The Fix

If the oil pump has been stuck, it is highly likely that you will need to take your saw to the dealer in order to get it repaired.

Frequently Asked Questions (FAQs)

What causes chain saw to bind?

Compression pinches your saw. Starting at the top on a log supported at both ends will close the cut and squeeze your saw. Everything is good until the log ends up compressing and binding against the bar.

What happens if you overtighten a chainsaw?

Too tight a saw chain can prohibit the chainsaw from turning or heating up. An overheated saw chain and guide bar can cause fires and shorten their lifespans.

Can chainsaws have too much chain oil?

If the chain and bar are oiled too much, debris may stick to them, making the chainsaw cut less efficiently and posing a safety risk.